Humble beginnings and a history of innovation make MSR one of the most trusted brands in the outdoors

This year marks the 50th anniversary for Seattle-based MSR. What started safety testing climbing gear evolved into one of the most recognized and trusted brands in the outdoor industry. Throughout its history, MSR developed products that left an indelible mark on the progression of outdoor safety, gear design, and the endeavors they helped execute.

The birth Mountain Safety Research

MSR was born in 1969 as a newsletter produced by Larry Penberthy, an engineer, inventor, and mountaineer. He was tasked by The Mountaineers to test the safety and performance of outdoor gear used in climbing, something long neglected.

MSR was born in 1969 as a newsletter produced by Larry Penberthy, an engineer, inventor, and mountaineer. He was tasked by The Mountaineers to test the safety and performance of outdoor gear used in climbing, something long neglected.

The Mountaineers’ and Penberthy’s resources ran thin, so Penberthy asked for a $3 donation for each newsletter issue, and he offered gear for sale to fund continued safety research and education. The income required MSR to become a business entity.

Penberthy’s original task of independently testing climbing gear, which often failed short of advertised specifications, spurred a desire to improve the safety of equipment and have third party manufacturing execute new designs. But Penberthy concluded that in house manufacturing would be superior, and MSR branded products were subsequently offered in the newsletter, the first being the MSR Snow Fluke anchor.

The innovation continues

MSR continued to design safer climbing gear, but they also introduced designs, technologies, and products that had a wider reach than it’s humble beginnings. Here is a sampling of how MSR has impacted the outdoor community and beyond.

The 1970s

- The first anti-balling plate for crampons made of PVC

- Rescue pulley for use with locking carabiners

- After discovering wood handles of ice axes to be too weak, MSR produces metal/fiberglass and metal/metal versions

- Brake bar device that works on many available carabiners

- Aluminum snow pickets

- Cabled chocks for the “clean climbing revolution”

- Remote fuel stove system improves safety and performance in the alpine, including the legendary multi-fuel Model 9, the precursor to the XGK.

- The aluminum heat shield to boost stove efficiency

- The first panel-loading backpacks

- The first helmet specifically for cyclists

- MSR headlamp becomes the first consumer-facing product that featured lithium batteries

- The first pit-zips

The 1980s

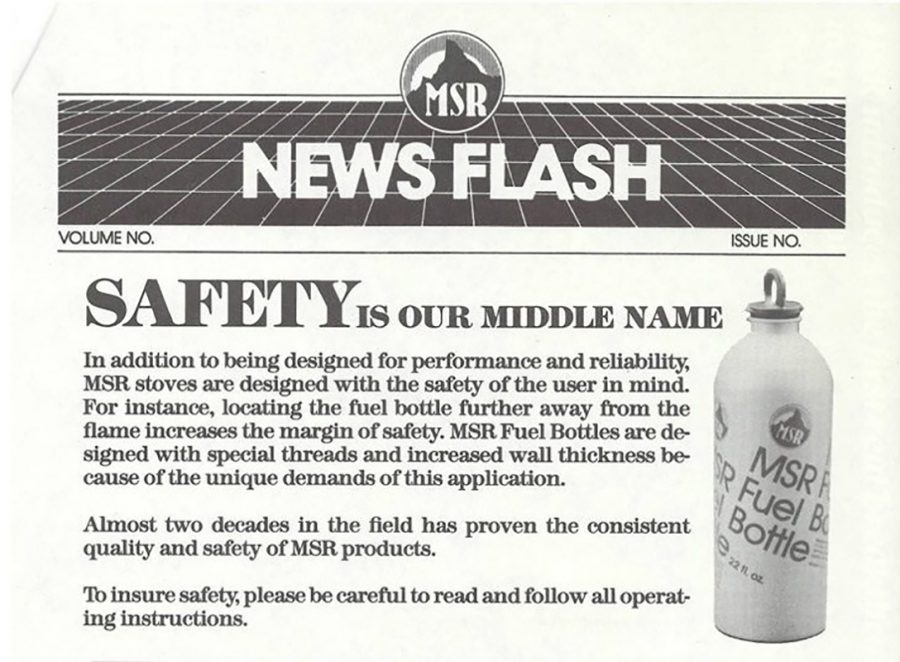

- The iconic MSR fuel bottle

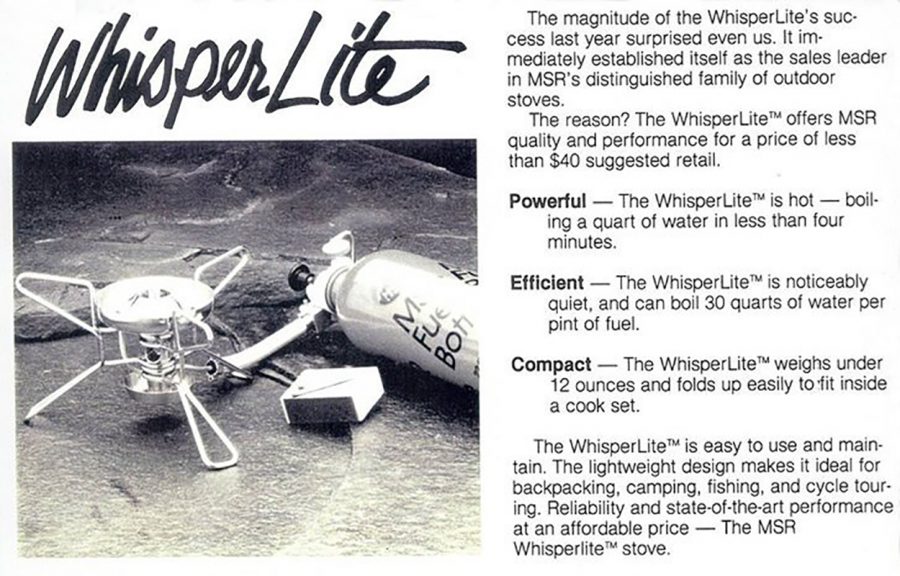

- The equally iconic MSR WhiperLite white gas stove

- The XPD cook set, which features the Heat Exchanger

- The Coyote Snow Picket remains almost unchanged

- The Shaker Jet to keep liquid stove fuel needles clean

The 1990s

- The Dromedary Bag water reservoir

- The Waterworks water filter

- Pioneers 3-Sigma engineering methodology for carabiners, which is adopted by all carabiner manufacturers and is still used today

- Worlds first molded-plastic (actually, a copolymer resin) snowshoe – The Denali Llama

- Sells its millionth stove

- Ceramic water filter elements and sets up an in-house microbiology lab

The 2000s

- The Pocket Rocket stove, a lightweight standard

- The MIOX water purifier; salt, electric current, and time are the only active ingredients

- The Reactor stove system; uses an enclosed radiant burner

- Becomes one of the first tent manufacturers to offer interior volume measurements

The 2010s

- Offers carbon fiber tent poles

- The WhisperLite Universal; burns both liquid fuel and butane canisters

Onward

Initially, MSR was a crusade to improve safety for people already putting themselves at risk, reducing the danger coming from gear. MSR wasn’t born as a profit-seeking effort; it was meant to support safety research and education by Larry Penberthy.

Over MSR’s 50-year life span, it has survived ownership changes, drastic deviations in the economics of manufacturing, an onslaught of competitors, and ever-changing market demands. But MSR still carries the corporate DNA instilled by Pemberthy; safety above all. MSR retains all design, engineering, testing, and the majority of manufacturing in-house, ensuring the traits of MSR’s early days carry forward and the products reflect the pride the company can rightfully and proudly display.

Personal conclusion

I have been climbing long enough to recognize and be an early adopter of many of the products on the above-listed timeline. Some of the products from the 1980s are still in use! Their storage sacks have long since disintegrated, but the hard goods still function, and I do not baby my gear at all. I can personally attest that the MSR gear I have used to be extremely durable, and durability also means safety.

One of my favorite attributes of MSR products is their field serviceability; this is unique in outdoor gear. And parts are available for home repair should the field repair not be a permanent solution. I have never failed to get an MSR product working in the field, regardless of how bad the situation seemed at the time.

I have visited MSR in Seattle; the engineers, microbiologists, combustion engineers, and others I met connect deeply to the products they help create, furthering my faith in the safety, durability, and functionality of the MSR products I use.